What’s New in Agricultural Track Technology and Dumper Design

Farmers see big changes on the field with new agricultural track technology and dumper designs. These upgrades help tractors handle mud and hills with ease. Check out the table below to see how modern tools boost productivity:

| Technology | Productivity Improvement |

|---|---|

| GPS-guided machinery | Up to 90% less overlap |

| AI-powered decision support systems | 15-20% yield increase |

Key Takeaways

- Modern agricultural tracks improve tractor grip and stability, helping farmers work confidently on mud, hills, and rough ground while protecting the soil.

- New dumper designs offer advanced safety features and smart technology that boost efficiency, reduce downtime, and support eco-friendly farming.

- Smart monitoring and automation tools help farmers make better decisions, increase crop yields, and save water and labor costs for more sustainable farming.

Breakthroughs in Agricultural Track Technology

Exceptional Traction and Stability

Farmers need equipment that can handle all types of ground. Modern agricultural track systems deliver just that. These tracks use deep treads and special rubber compounds to grip mud, sand, and hills. Operators feel more confident because their machines stay steady, even on slopes or rough ground.

- Reduced ground pressure by up to 75% compared to wheeled machines helps protect the soil and keeps it healthy.

- Superior flotation lets tractors work longer in wet or muddy fields.

- Aggressive, self-cleaning tread patterns provide strong grip and prevent mud from sticking.

- Advanced rubber compounds keep the tracks flexible and grippy, even when temperatures change.

- Wide footprints spread the machine’s weight, making tipping less likely and improving balance.

Note: Our agricultural rubber tracks use these advanced designs to give farmers the traction and stability they need for every season.

Durability and Longevity in Agricultural Track Systems

Farmers want tracks that last. New agricultural track systems use high-quality rubber and reinforced parts. These upgrades mean less wear and fewer repairs. Tracks now resist cuts, tears, and chunking, so they stay strong through heavy use.

- Reinforced internal structures help tracks last longer and protect against damage.

- Multi-bar tread patterns create more contact points with the ground, balancing traction and comfort.

- Proper track tensioning is important. If the tension is right, tracks last longer and work better.

- Tracks are designed to absorb impacts and reduce vibration, which helps the machine and the operator.

Our agricultural rubber tracks are built for long service life. They help farmers save money on maintenance and keep their equipment running smoothly.

Smart Monitoring and Automation

Technology now plays a big role in farming. Smart monitoring and automation features in agricultural track systems help farmers work smarter, not harder. Real-time data collection shows how machines are working. Automated alerts warn operators about problems before they get worse.

- Real-time monitoring helps spot issues early and keeps machines running longer.

- Automated alerts and predictive maintenance reduce downtime and prevent breakdowns.

- Integration with farm management systems improves scheduling and control.

- Automation reduces mistakes and keeps operations consistent.

A real-world example comes from a company that added smart monitoring to their machines. They gained 17 extra productive hours per employee each month and saw less downtime. These features help farmers get more done and keep their equipment in top shape.

Recent advances in AI and digital tools also help farmers make better decisions. These tools use big data and machine learning to predict crop needs and improve yields. Farmers can now adjust planting, watering, and fertilizing based on real-time information, making their operations more efficient and sustainable.

Next-Generation Dumper Design

Advanced Load Handling and Safety Features

Modern dumpers bring a new level of safety and control to the field. They come packed with features that help operators handle heavy loads with confidence. Many next-generation dumpers include rollover protection structures (ROPS) and advanced braking systems. These features keep both the operator and the machine safe, even on steep hills or rough ground.

- Operator cabins now offer better visibility and comfort, which helps reduce fatigue during long workdays.

- Smart systems like telematics monitor machine health and operator actions in real time, making it easier to schedule maintenance and avoid breakdowns.

- Automation and semi-autonomous controls lower the risk of mistakes and boost safety.

- Compact designs let dumpers move safely in tight spaces, while electric and hybrid models run quietly and safely in busy areas.

Note: Safety warnings on dashboards and easy-to-access controls help operators stay alert and in control at all times.

Integration with Precision Agriculture Technologies

Today’s dumpers do more than just haul loads. They connect with smart farm systems to make every job more efficient. IoT sensors and GPS tracking let farmers see where each dumper is and how it’s working. Some dumpers even use AI to unload automatically and adjust routes for the best results.

- Manufacturers now team up with tech companies to create connected dumpers.

- These machines collect and share data, helping farmers plan better and fix problems before they grow.

- Customizable dumper platforms fit different crops and tasks, making them a flexible choice for any farm.

Eco-Friendly and Sustainable Dumper Solutions

Farmers care about the land, so new dumper designs focus on protecting the environment. Electric dumpers and those with hybrid engines cut down on emissions and noise. Many models use eco-friendly materials and support recycling efforts during manufacturing.

- Electrically powered dumpers replace old hydraulic systems, lowering carbon footprints.

- Dust control features help meet strict environmental rules.

- Telematics track fuel use and help operators work more efficiently, reducing waste and pollution.

These changes mean farmers can work smarter, safer, and greener every day.

Real-World Applications of Agricultural Track and Dumper InnovationsNavigating Complex Terrains with Confidence

Farmers often face tough ground, from muddy fields to steep hills. Modern agricultural track systems help them move through these areas with ease. Studies show that skilled operators spend more time in challenging terrain because they trust their equipment. This confidence comes from advanced track designs that grip the ground and keep machines stable. Farmers can now reach places that once seemed impossible, making every acre count.

Enhancing Productivity and Reducing Downtime

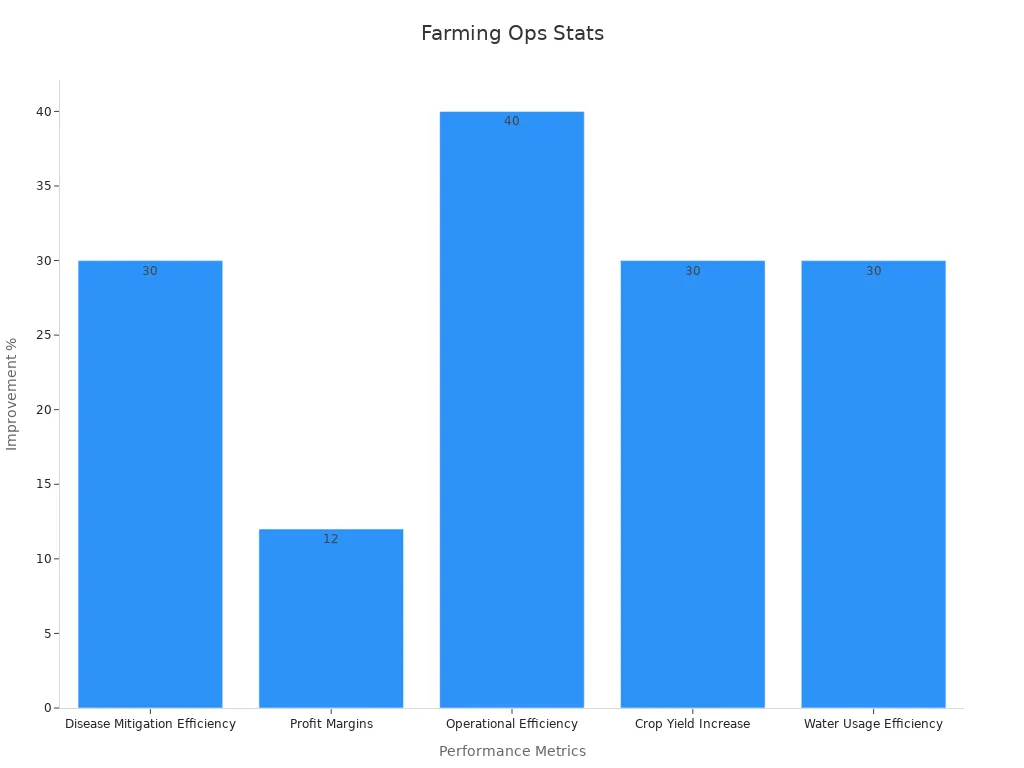

New technology brings big gains to the farm. Data analytics and smart sensors help farmers plan their work and fix problems before they grow. Here are some real results:

- Farms using predictive analytics saw a 30% jump in crop yield.

- Real-time sensors let workers target their efforts, cutting waste and boosting output.

- GPS and automation save time and fuel, while advanced machines protect crops during harvest.

| Performance Metric | Improvement Percentage |

|---|---|

| Operational Efficiency | 40% |

| Crop Yield Increase (Case Study) | 30% |

| Water Usage Efficiency (Case Study) | 30% |

Supporting Sustainable and Efficient Farming

Farmers want to protect the land for future generations. Innovations in dumper and track technology help them do just that. Recent data shows an 18% rise in water quality scores and a 15% drop in greenhouse gas emissions. Energy use for crop production also fell by 15%. These changes mean farms can grow more while using fewer resources. The right agricultural track and dumper equipment support both the environment and the bottom line.

Selecting the Right Agricultural Track and Dumper Equipment

Evaluating Farm Size and Terrain Requirements

Every farm is different. Some cover hundreds of acres, while others are much smaller. The right equipment depends on the size of the land and the type of ground. Large farms with rolling hills or muddy fields need machines that can handle tough conditions. An agricultural track system works well for these areas because it gives strong grip and keeps tractors steady. Smaller farms may need compact dumpers that fit into tight spaces. Farmers should look at their land and think about what jobs they do most often.

Matching Features to Operational Demands

Farmers have many tasks each season. Some need to plow, plant, and harvest. Others focus on hauling heavy loads or working in wet fields. The best equipment matches these needs. For example, a dumper with advanced safety features helps when moving big loads on slopes. Tracks with deep treads work well in muddy fields. Farmers should make a list of their most important jobs and choose machines that help them work faster and safer.

Tip: Ask other farmers about their favorite features. Real-world advice can help narrow down the choices.

Considering Long-Term Value and Upgrade Potential

Choosing new equipment is a big decision. Farmers want machines that last and can be upgraded in the future. However, a recent review shows that there are not many long-term studies on how equipment upgrades affect farm finances. This makes it hard to know which machines will give the best value over time. Farmers should look for brands that offer upgrade options and strong support.

When thinking about long-term value, it helps to check several market factors:

- Review net cash farm income trends and forecasts.

- Assess working capital and balance sheets.

- Examine commodity prices and their effect on profits.

- Analyze new, used, and auction equipment markets.

- Evaluate production records, cash flow, and payment capacity.

- Consider financing options like loans or leases.

- Factor in extra costs such as transportation and buyer’s fees.

- Explore sharing equipment or custom services to save money.

Smart choices today can help farms stay strong for years to come.

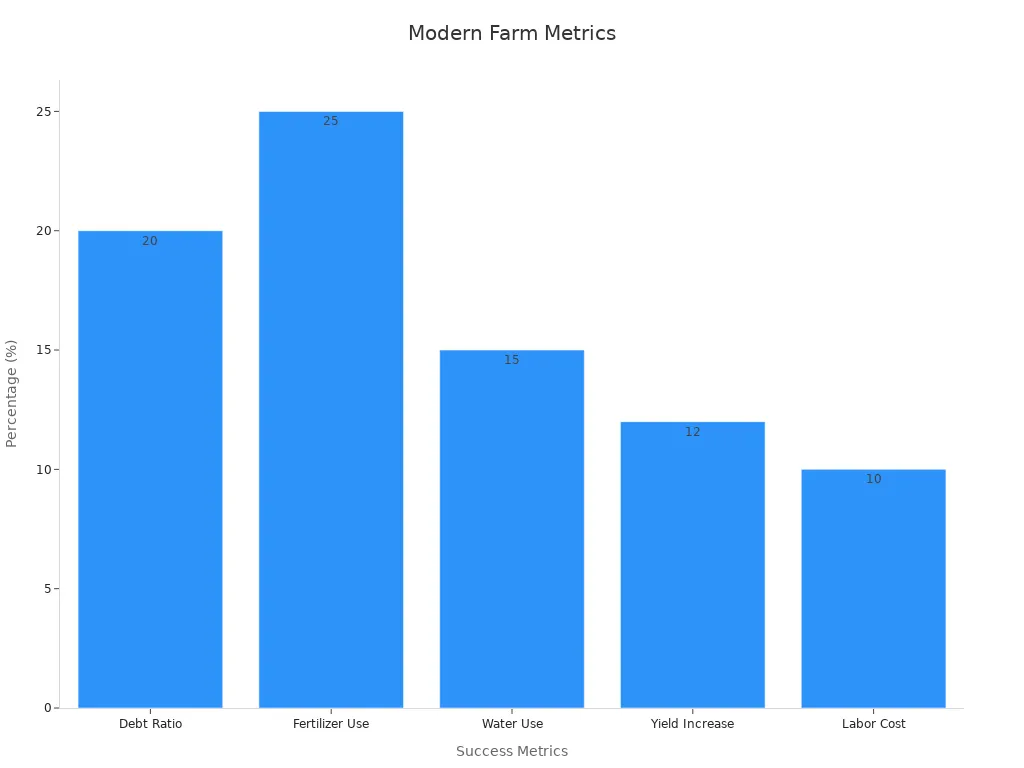

Modern farms see real gains with advanced track and dumper technology. IoT tools and smart systems help farmers use less water, cut costs, and grow more. Field trials show a 12% yield increase and 15% less water use.

| Success Metric | Result | Benefit |

|---|---|---|

| Yield Increase | 12% | More crops, higher profits |

| Water Usage Reduction | 15% | Better resource management |

| Labor Cost Reduction | 10% | Lower expenses |

Farmers can reach out for tailored solutions: Email: [email protected], Wechat: 15657852500, LinkedIn

FAQ

How do agricultural rubber tracks improve tractor performance?

Farmers see better traction and stability. These tracks help tractors move easily over mud, sand, and hills. Operators finish jobs faster and with less stress.

What makes these tracks last longer than others?

Manufacturers use high-grade rubber and strong reinforcements. This design resists wear and damage. Farmers spend less time on repairs and more time working.

Can these dumpers connect with smart farm systems?

Yes! Many new dumpers use IoT sensors and GPS. Farmers track their machines, plan routes, and get real-time updates right from their phones.

Media Contact

Company Name: Gator Track Co., Ltd.

Email: Send Email

Country: China

Website: https://www.gatortrack.com/